Zhengfeng

Zhengfeng

Jan 08,2026

Jan 08,2026

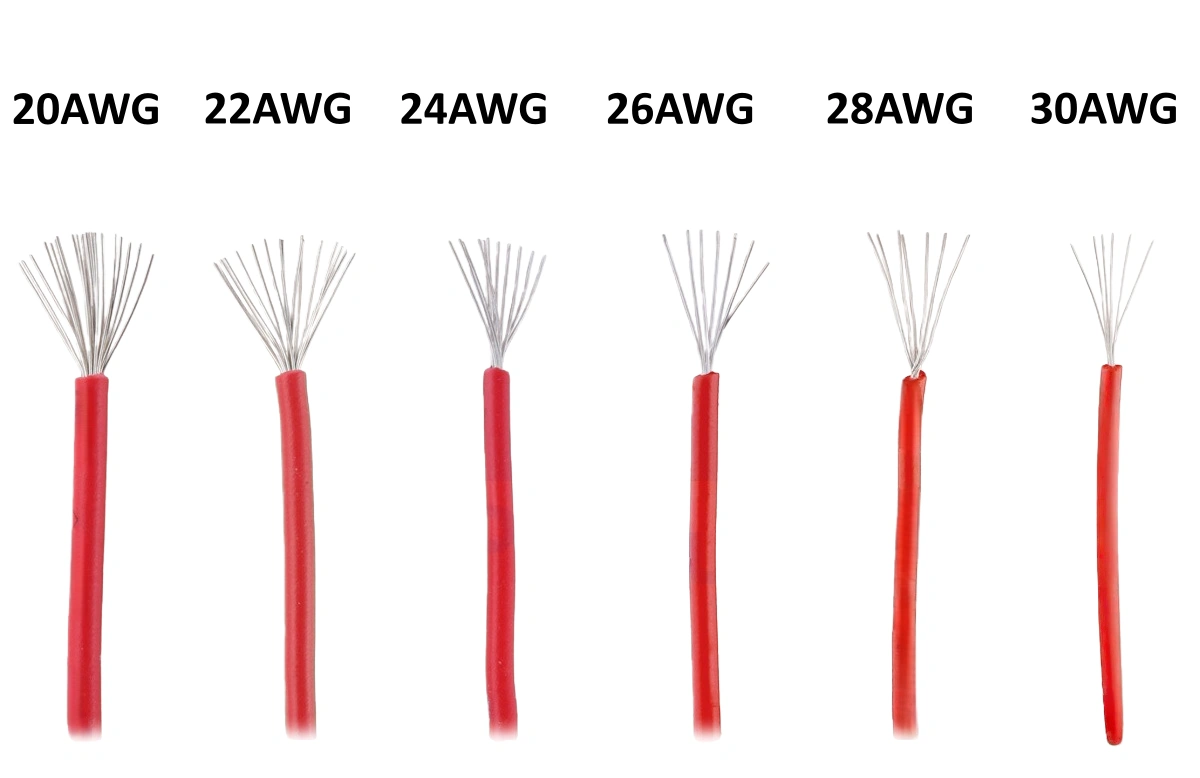

The AWG system originated in 1857, developed by J.R. Brown, and was initially called the Brown & Sharp wire gauge. This system uses numbers to represent the diameter of the wire—the smaller the number, the thicker the wire. For example, common household wires might be 12 or 14 AWG, while finer electronic wires might be 24 or 26 AWG.

This seemingly reversed numbering system (smaller numbers, thicker wires) stems from the historical process of wire manufacturing: the wire is drawn through progressively narrower holes. Each time it passes through a smaller hole, the wire becomes thinner, and the AWG number increases. AWG 0000 (4/0) is the thickest standard size, with a diameter of approximately 0.46 inches, while AWG 40 is one of the thinnest, with a diameter of only 0.0031 inches.

| AWG |

Diameter (mm) |

Cross-sectional Area (mm²) |

Typical Applications |

| 4/0 | 11.68 | 107 | Main power supply inlet, large industrial equipment |

| 2/0 | 9.27 | 67.4 | Main power distribution in houses, electric vehicle chargers |

| 2 | 6.54 | 33.6 | Dedicated circuits for large appliances |

| 6 | 4.11 | 13.3 | Kitchen appliances, electric water heaters |

| 10 | 2.59 | 5.26 | Dryers, small air conditioners |

| 12 | 2.05 | 3.31 | General household sockets, lighting circuits |

| 14 | 1.63 | 2.08 | Lighting circuits, low-power devices |

| 16 | 1.29 | 1.31 | Low-voltage lighting, car audio systems |

In electrical engineering and electronics, AWG is more than just a unit of measurement; it's a key determinant of safety, efficiency, and performance:

Current Carrying Capacity: Thicker wires (lower AWG numbers) can safely carry more current without overheating.

Resistance: Thinner wires have higher resistance, leading to greater voltage drop and energy loss.

Flexibility: Thinner wires are more flexible and suitable for space-constrained applications.

Cost Considerations: Thicker wires use more material, thus costing more.

Choosing the correct AWG is crucial for the safe operation of any electrical system. Incorrect specifications can lead to overheating, fire risks, or poor system performance.

Basic Rule: Choose according to the circuit's rated current.

Circuit Protection Devices Determine Maximum Current: The wire specification must be able to carry at least the rated current of the circuit breaker or fuse.

Continuous vs. Intermittent Loads: For continuous loads (operating for more than 3 hours), use a wire with a higher rated value.

Practical Tip: When calculating the total current of an appliance, use the formula: Power (Watts) ÷ Voltage (Volts) = Current (Amps)

Why is length important? The longer the wire, the greater the resistance, and the more significant the voltage drop. Excessive voltage drop can lead to decreased equipment performance or even damage.

Teflon wire: UL1332 18AWG, 22AWG, and 24AWG are commonly used wire sizes.

Silicone wire: Commonly purchased specifications include 8AWG, 10AWG, 12AWG, and 24AWG.

Lamp cord: 18AWG and 20AWG are preferred.

PVC electronic wire: 8AWG, 10AWG, 18AWG, and 26AWG.

Although AWG itself is unrelated to voltage, the insulation rating must match the voltage:

Household circuits: 300V or 600V insulation is sufficient.

Industrial equipment: 1000V or higher insulation rating may be required.

High-voltage applications: In addition to sufficient insulation, corona discharge issues must be considered.

Non-standard AWG wires (such as 11, 13, 15) may be difficult to find and more expensive. Standard sizes (10, 12, 14, 16, etc.) are easier to obtain and more affordable.

If you encounter difficulties in practical applications and are unsure how to choose the right wire or wire size, please contact the Zhengfeng Wire&Cable team immediately. We have teflon wire, silicone wire, pvc cable, lamp cord, and provide 24-hour online service and cable application solutions for multiple industries.

Tel/WhatsApp/WeChat: +86 138 2929 2517 / +86 147 4930 7879

Email: manager01@wire-cablemanufacturer.com

Guangdong Zhengfeng Wire&Cable Co., Ltd. look forward to cooperating with you and creating a win-win situation!