Zhengfeng

Zhengfeng

Sep 04,2025

Sep 04,2025

A senior electronic engineer, after completing the wiring of an industrial control box, noticed that some wires began to soften and deform in a high-temperature environment, while others remained perfectly stable.The reason behind this difference lies in the UL wire type.Each UL electronic wire model has its own specific technical parameters, and only by matching these parameters with the application scenario can we ensure safe wire usage.

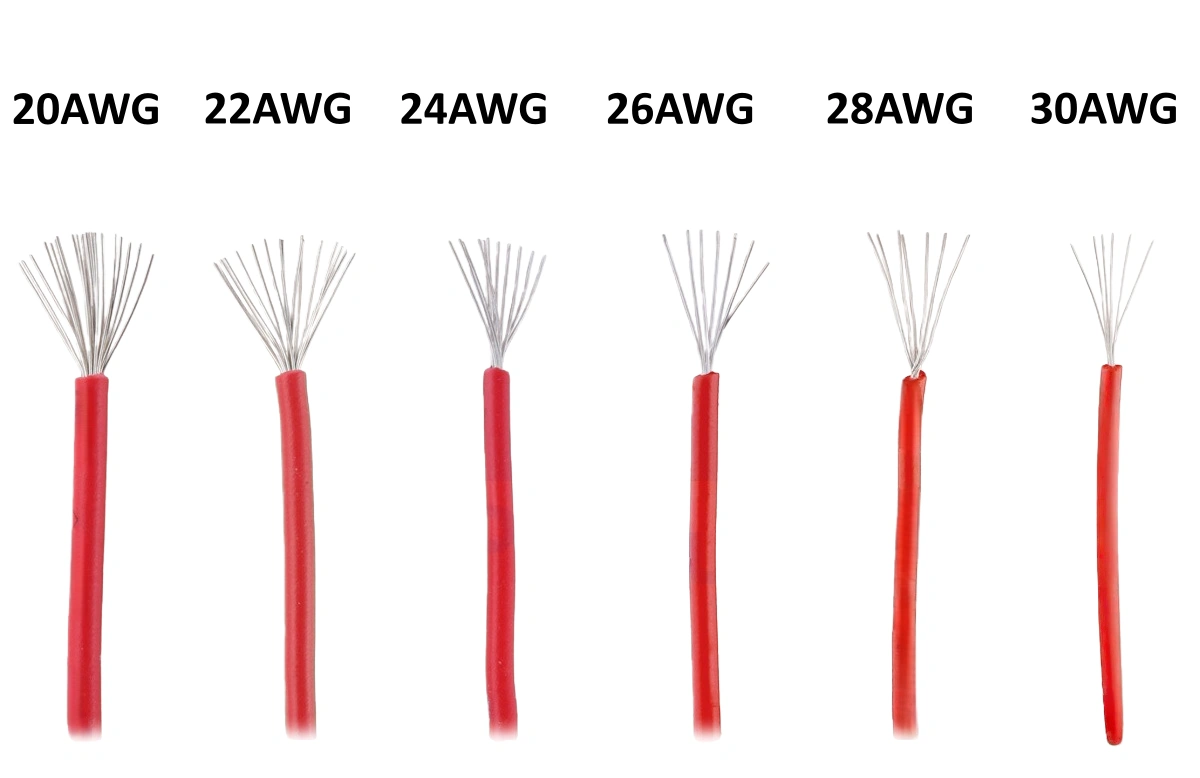

In modern electronic devices, wires are not just pathways for current—they are essential for safety.UL (Underwriters Laboratories) certification has become one of the most widely recognized global safety standards.These standards ensure that wires can operate safely under specific voltage, temperature, and environmental conditions.UL-certified electronic wires are produced according to the American Wire Gauge (AWG) system, in which a smaller number indicates a thicker wire with greater current-carrying capability.

Whether it is a home theater system, car audio, or industrial control equipment, all rely on rigorously tested electronic wires. These wires not only conduct electricity but also need to offer high-temperature resistance, flame retardancy, and chemical corrosion resistance.

UL1007 is a PVC-insulated, single-core, thermoplastic wire suitable for low voltage (300V) and medium-temperature (80°C) environments.It typically uses tinned copper conductors, which prevents oxidation and makes soldering easier.From its technical specifications:

Rated voltage: 300V

Temperature rating: 80°C

AWG range: 28–16AWG

For example, the commonly used 24AWG has:

Diameter: approx. 0.51mm

Cross-section: approx. 0.205mm²

Safe current capacity: 0.57A–0.76A

These characteristics make UL1007 ideal for internal wiring of consumer electronics such as smartphones, computers, audio devices, and small appliances. Its flexibility and solderability also make it popular among DIY hobbyists and repair technicians.

Authentic UL1007 Identification:

The outer jacket of genuine UL1007 wire should include clear markings, such as UL factory number (e.g., E522608), standard model (AWM 1007), wire gauge (e.g., 24AWG), and temperature/voltage rating (80°C 300V).

Missing or unclear markings may indicate counterfeit or uncertified wires.

UL1015 is also PVC-insulated but designed for more demanding environments.

It has:

Rated voltage: 600V

Temperature rating: 105°C—significantly higher than UL1007.

UL1015 typically covers 18–10AWG, focusing on thicker wires capable of carrying higher currents, making it suitable for high-power applications.

Its physical structure is more robust, often featuring 0.79mm insulation thickness, capable of passing UL VW-1 and CSA FT1 flame tests.

It also provides resistance to acid, alkali, oil, moisture, and mold.

These characteristics make UL1015 the preferred choice for:Industrial equipment\Motor internal wiring\Automotive electrical systems\Any environment requiring high temperature and voltage resistance.

Although UL1007 and UL1015 look similar, their performance parameters differ greatly. Understanding the differences is crucial when selecting the correct wire.

|

Parameter |

UL1007 Electronic Wire |

UL1015 Electronic Wire |

|

Rated Voltage |

300V |

600V |

|

Temperature Rating |

80°C |

105°C |

|

Main AWG Range |

28–16AWG |

18–10AWG |

|

Typical Applications |

Consumer electronics, small appliances |

Industrial equipment, automotive electrical,High-temperature equipment wiring |

|

Flame Test |

Passes VW-1 & CSA FT1 |

Passes VW-1 & CSA FT1 |

When choosing between UL1007 and UL1015, consider the following:

Voltage Requirement:

Below 300V → UL1007 is sufficient

Near or above 300V → UL1015 is recommended

Temperature Environment:

Below 80°C → UL1007

80–105°C → UL1015 is necessary

Current Load:

Choose the correct AWG based on current.

For example, 24AWG UL1007 safely carries 0.57–0.76A, while thicker wires (e.g., 16AWG) support higher currents.

Cost Efficiency:

UL1007 is typically more cost-effective when performance requirements allow.

Buying truly UL-certified UL1007 or UL1015 wires is essential for safety and reliability.

You can check the UL official database “Product iQ” to verify wire specifications and confirm whether the supplier's wire products are UL certified.

Taking Guangdong Zhengfeng Wire & Cable Co., Ltd. as an example, professional manufacturers like this provide fully certified UL1007 and UL1015 wires along with comprehensive technical support.

Their services include:

If you have any more ideas, please contact us.

Guangdong Zhengfeng Wire&Cable Co., Ltd.

Tel/WhatsApp/WeChat: +86 138 2929 2517 / +86 147 4930 7879

Email: manager01@wire-cablemanufacturer.com