Zhengfeng

Zhengfeng

Dec 06,2025

Dec 06,2025

Comprehensive Guide

I. Decrypting 3530 Silicone Rubber Wire: Definition and Core Technical Specifications

II. Scenario Orientation: Where Does UL3530 Silicone Rubber Insulated Cable Shine?

1. Industrial High-Temperature Equipment Field

2. New Energy and Automobile Electronics Industry

4. Extreme Environment Operations (Polar Regions, Chemical Industry, Nuclear Power)

5. Precision Electronic Equipment and Robotics

III. Purchasing Guide: How to Choose the Right UL3530 Silicone Rubber Wire?

1. Clarify the Core Requirements of the Application Scenario

2. Strictly Verify Product Certifications

3. Pay Attention to the Quality of Conductor and Insulation Materials

4. Choose Suppliers with Strong Comprehensive Strength

5. Focus on Customization Capability and After-Sales Service

IV. Choose Guangdong Zhengfeng Wire&Cable: 25 Years of Ingenuity, Guarding Your Safe Operation

In the fields of industrial production, electronic equipment, medical devices, and new energy, wires and cables are the "blood vessels" of energy transmission and signal communication. Their performance directly determines the stability, safety, and service life of the entire equipment system. Among numerous wire and cable products, UL3530 silicone wire, as a high-performance Silicone Rubber Wire, has won widespread recognition in the global market with its excellent environmental adaptability and reliable electrical performance. Especially the UL3530 Silicone Rubber Insulated Cable, which has passed strict international certifications, has become the preferred choice for enterprises pursuing high-quality and high-safety solutions. So, what is the core connotation of 3530 silicone rubber wire? What are its technical specifications that stand out? Which scenarios is it most suitable for? And how to choose a product that truly fits your needs? This article will give you a comprehensive and in-depth interpretation.

I. Decrypting 3530 Silicone Rubber Wire: Definition and Core Technical Specifications

Before understanding the technical specifications of 3530 silicone rubber wire, we first need to clarify its core definition. 3530 silicone rubber wire, also known as UL3530 silicone wire, is a special wire with silicone rubber as the insulation material and multi-strand tinned copper wire as the conductor. It is specially designed for environments with high requirements for temperature resistance, corrosion resistance, and flexibility. The UL3530 Silicone Rubber Insulated Cable is named because it fully complies with the UL3530 standard formulated by Underwriters Laboratories (UL), a well-known international certification body, which means its quality and safety have passed strict authoritative verification.

As the core of the product's competitiveness, the technical specifications of UL3530 silicone wire directly determine its application scope and service performance. The following is a detailed sorting out of its key parameters, and a comparative analysis with ordinary Silicone Rubber Wire and other models of high-temperature wires to highlight its unique advantages:

| Technical Parameter |

UL3530 Silicone Rubber Insulated Cable |

Ordinary Silicone Rubber Wire (Non-UL3530) |

Common PVC Wire |

| Rated Temperature |

-60℃ to +155℃ (long-term stable operation) |

-40℃ to +150℃ |

-15℃ to +70℃ |

| Rated Voltage |

600V |

300V-600V (unstable) |

300V |

| Conductor Material |

Multi-strand tinned copper wire (stranded structure, good flexibility) |

Bare copper wire or tinned copper wire (uneven quality) |

Bare copper wire (single-strand or multi-strand) |

| Conductor Specification Range |

AWG 4/00 - AWG 26 (covers most industrial and electronic needs) |

AWG 22 - AWG 10 (narrower range) |

AWG 24 - AWG 8 |

| Insulation Material |

High-purity silicone rubber (complies with UL standards, low smoke and halogen-free) |

Ordinary silicone rubber (possible impurities) |

PVC (contains halogen, easy to age) |

| Test Voltage |

2000V (no breakdown for 5 minutes) |

1500V-2000V |

1000V |

| Minimum Bending Radius |

7.5 × cable diameter (easy to install in narrow spaces) |

8 × - 10 × cable diameter |

10 × - 15 × cable diameter |

| Key Certifications |

UL3530, RoHS, ISO9001 |

Partial RoHS certification |

Basic national standard certification |

It can be seen from the above comparison that UL3530 silicone wire has obvious advantages in temperature resistance range, voltage bearing capacity, flexibility, and safety certification compared with ordinary Silicone Rubber Wire and PVC wire. Its multi-strand tinned copper conductor not only ensures excellent electrical conductivity but also has strong anti-oxidation ability, which can effectively extend the service life of the wire in harsh environments. The high-purity silicone rubber insulation layer has good resistance to chemical corrosion, UV radiation, and ozone, and will not soften, carbonize or crack even in long-term high-temperature operation, ensuring the stability of electrical performance.

The excellent comprehensive performance of UL3530 silicone wire makes it widely used in various harsh and high-demand fields. Understanding its applicable scenarios can help enterprises accurately match their own needs and avoid the waste of resources caused by improper selection. The following are the typical application scenarios of 3530 silicone rubber wire, combined with actual cases to analyze its core value:

In metallurgy, glass manufacturing, plastic processing and other industries, a large number of high-temperature equipment such as blast furnaces, annealing furnaces, and injection molding machines need wires that can withstand long-term high temperatures. The operating temperature of these equipment is often between 100℃ and 150℃, and ordinary wires will accelerate aging and even cause short circuits due to insulation layer failure. UL3530 Silicone Rubber Insulated Cable can work stably at -60℃ to +155℃, and can withstand instantaneous high temperatures of up to 180℃, which is perfectly suitable for the power connection and signal transmission of high-temperature heating elements and control systems. For example, in a glass factory, the temperature near the melting furnace is as high as 160℃, and the UL3530 silicone wire used for the signal transmission of temperature sensors has been operating stably for more than 5 years without any failure, while the ordinary silicone wire needs to be replaced every 1-2 years.

With the rapid development of new energy vehicles, photovoltaic power generation, and energy storage systems, the requirements for wires in terms of high temperature resistance, flame retardancy, and safety are increasingly strict. The battery pack of new energy vehicles will generate a lot of heat during charging and discharging, and the ambient temperature can reach 120℃. The UL3530 silicone wire is used for the internal wiring of the battery management system (BMS) and the connection of motors, which can effectively resist high-temperature erosion and ensure the safe operation of the vehicle. In addition, in photovoltaic inverters and energy storage cabinets, UL3530 Silicone Rubber Insulated Cable also plays an important role with its excellent electrical insulation performance and weather resistance, adapting to the outdoor harsh environment of alternating hot and cold.

Medical equipment such as X-ray machines, radiotherapy equipment, and ventilators have stringent requirements for the safety, stability, and environmental friendliness of their wiring. On one hand, these devices typically operate in environments requiring frequent sterilization, necessitating wiring that can resist corrosion from chemical disinfectants such as alcohol and ethylene oxide. On the other hand, the wiring must be low-smoke and halogen-free to prevent the release of toxic gases in the event of a fire, which could endanger the safety of medical staff and patients. We can choose more environmentally friendly platinum silicone material, whose insulation layer is non-toxic and odorless, and can withstand repeated sterilization. Simultaneously, its stable electrical performance ensures accurate signal transmission for medical equipment, making it an ideal choice for medical equipment manufacturers.

In polar scientific research stations, chemical workshops, nuclear power plants and other places, wires need to face extreme challenges such as ultra-low temperature, strong corrosion, and high radiation. In the Antarctic scientific research station with a temperature as low as -60℃, ordinary wires will become hard and brittle and even break, while UL3530 silicone wire can still maintain good flexibility and normal electrical conductivity. In chemical workshops, it can resist the erosion of mineral oil, acid and alkali solutions, and ensure long-term stable operation. In nuclear power plants, the modified UL3530 Silicone Rubber Insulated Cable can withstand a certain dose of radiation, and its insulation layer is not easy to degrade, which provides a reliable guarantee for the safe operation of nuclear power equipment.

Precision electronic equipment such as computers, communication equipment, and industrial robots have high requirements for the flexibility and miniaturization of wires. The minimum bending radius of UL3530 silicone wire is only 7.5 times the cable diameter, which can be easily routed in narrow spaces inside the equipment. For industrial robots that need frequent movement and bending, UL3530 silicone wire has excellent fatigue resistance, which can withstand millions of bending times without breaking, effectively improving the reliability and service life of the robot.

Although UL3530 silicone wire has excellent performance, if you do not grasp the key points in the purchasing process, you may encounter problems such as mismatched specifications, unqualified quality, and poor after-sales service. Combining years of industry experience and market feedback, the following are 5 core purchasing suggestions to help you avoid pitfalls and choose the most suitable product:

Before purchasing, you must first clarify the key parameters such as the operating temperature, rated voltage, current load, and installation space of the wire in the actual application scenario. For example, if it is used in high-temperature industrial equipment, focus on confirming that the rated temperature of the wire meets the actual operating temperature (it is recommended to reserve a 10%-20% margin); if it is used in precision electronic equipment, pay attention to the flexibility and bending radius of the wire. At the same time, it is necessary to clarify whether there are special requirements such as corrosion resistance, radiation resistance, and flame retardancy, so as to accurately match the product specifications.

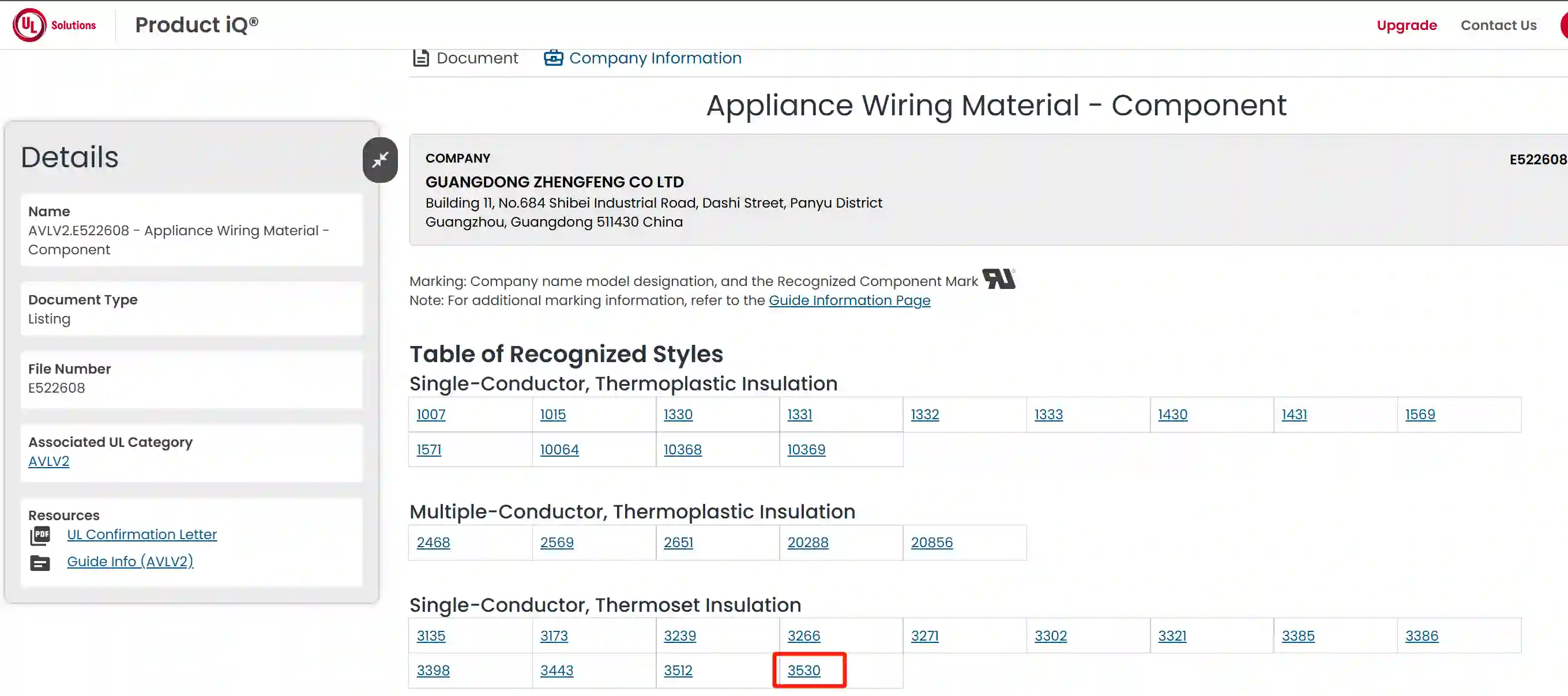

UL3530 silicone conductor quality certification is crucial for assurance. When purchasing, always request complete certification documents from suppliers, including UL3530 certification, RoHS certification, and ISO9001 quality management system certification. Be especially wary, as some unscrupulous vendors may use fake certifications to endorse inferior products. We recommend verifying the authenticity of certifications on the official website of the certification body. For example, log in to the UL website and enter certification file number E522608 to find that model 3530 under that file has passed UL certification.

The quality of conductor and insulation materials directly determines the performance of UL3530 Silicone Rubber Insulated Cable. The conductor should be made of high-purity tinned copper wire, which has good electrical conductivity and anti-oxidation performance. You can check the cross-section of the conductor to see if it is uniform in thickness and free of impurities. The insulation layer should be made of high-purity silicone rubber, which has a smooth surface, no bubbles, and uniform thickness. You can test the flexibility of the wire by hand; the high-quality silicone rubber wire is soft and elastic, and will not feel hard or brittle.

The strength of the supplier is related to the stability of product quality and after-sales service. It is recommended to choose suppliers with rich production experience, perfect production equipment, and standardized quality management systems. Suppliers with 20 years or more of production experience usually have mature production processes and rich technical accumulation, which can better solve various problems in the production process. At the same time, pay attention to whether the supplier has the ability to export products, because export-oriented enterprises usually need to meet the quality standards of various countries, and their product quality is more reliable.

Different enterprises have different needs for wires. Some special scenarios may require wires of special specifications, materials, or lengths. Therefore, when purchasing, it is necessary to confirm whether the supplier has personalized customization capabilities, such as customizing conductors of different specifications, insulation materials with special performance, or wires of fixed lengths. In addition, perfect after-sales service is also essential, including pre-sales technical consultation, in-sales quality inspection, and after-sales problem solving. Suppliers with 24-hour customer service can respond to customer needs in a timely manner and provide professional solutions.

When it comes to choosing a reliable UL3530 silicone wire supplier, Guangdong Zhengfeng Wire&Cable Co., Ltd. has become the first choice of many enterprises around the world with its 25 years of production experience and excellent product quality. Since its establishment, we have been committed to the R&D, production, and sales of high-performance wires and cables, focusing on the field of Silicone Rubber Wire, and have accumulated rich experience and technical achievements.

As a professional manufacturer of UL3530 Silicone Rubber Insulated Cable, we have strict control over product quality. From the selection of raw materials, we use high-purity tinned copper conductors and imported high-quality silicone rubber, and each batch of raw materials must undergo strict quality inspection before entering the factory. In the production process, we adopt advanced production equipment and standardized production processes, and implement full-process quality monitoring to ensure that each meter of UL3530 silicone wire meets the requirements of international standards. Our products have passed UL3530, RoHS, ISO9001 and other authoritative certifications, and have been exported to Europe, America, Southeast Asia, Africa and other dozens of countries and regions, with partners all over the world.

We deeply understand that different customers have different needs. Therefore, we provide a full range of customization services, which can customize wires of various specifications, materials, and lengths according to customers' actual application scenarios. Whether you need UL3530 silicone wire for high-temperature equipment, medical devices, or new energy vehicles, our professional technical team can provide you with personalized application solutions. At the same time, we have a fast delivery system, which can ensure that the customized products are delivered to customers on time, helping customers shorten the production cycle and improve market competitiveness.

Customer satisfaction is our eternal pursuit. We have set up a 24-hour full-time customer service team, which can answer your questions about product specifications, application scenarios, and customization services at any time through Tel, WhatsApp, or WeChat. Before sales, our technical consultants will communicate with you in detail to understand your actual needs and recommend the most suitable products for you; during sales, we will provide real-time feedback on the production progress and conduct strict quality inspection on the products before delivery; after sales, if you encounter any problems in the use process, our after-sales team will respond quickly and provide professional solutions to ensure that your production operation is not affected.

In addition to UL3530 silicone wire, we also provide a complete range of ground wires of various types, which can meet the needs of different industries. Our products are widely used in industrial manufacturing, new energy, medical equipment, automobile electronics and other fields, and have won unanimous praise from customers with reliable quality and thoughtful service.

UL3530 silicone wire, as a high-performance Silicone Rubber Wire, has become an indispensable core component in various harsh environments and high-demand fields with its excellent temperature resistance, corrosion resistance, flexibility, and safety performance. When choosing UL3530 Silicone Rubber Insulated Cable, enterprises must clarify their own needs, strictly verify product certifications, and choose suppliers with strong comprehensive strength and perfect after-sales service.

Guangdong Zhengfeng Cable Co., Ltd. has been deeply rooted in the industry for 25 years, consistently committed to providing customers with high-quality, safe, and reliable cable products through craftsmanship and relentless pursuit of excellence. Whether for standard products or customized needs, we can provide comprehensive solutions. We also have in-depth knowledge of UL standards and a technical team familiar with these standards. Choosing Zhengfeng means choosing trustworthy quality and peace of mind. We look forward to establishing a long-term and stable cooperative relationship with you, working together to create a better future.

Guangdong Zhengfeng Wire&Cable Co., Ltd.

Tel/WhatsApp/WeChat: +86 138 2929 2517 / +86 147 4930 7879

Email: manager01@wire-cablemanufacturer.com