Zhengfeng

Zhengfeng

Dec 08,2025

Dec 08,2025

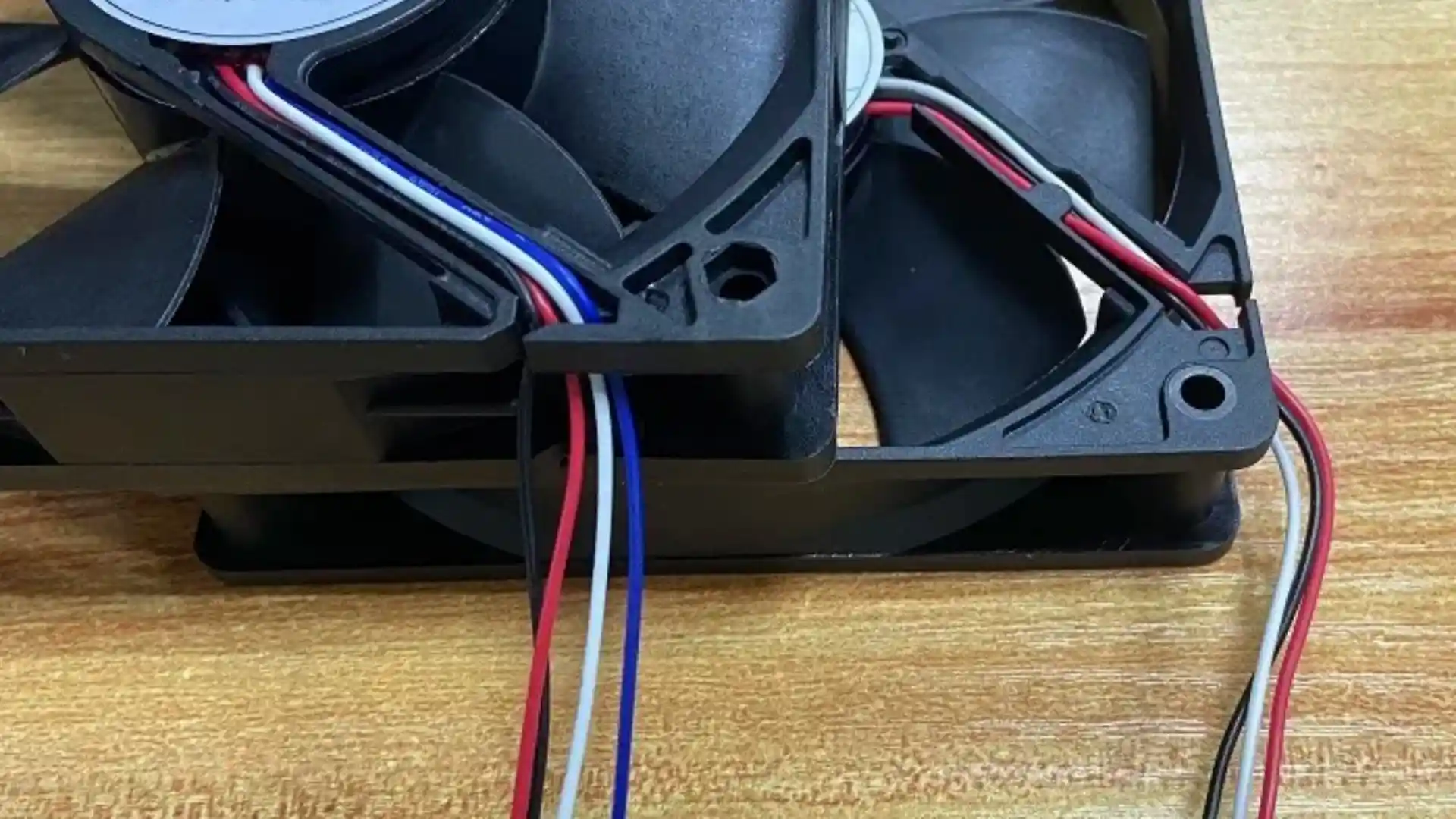

In the operating system of electronic equipment, cooling fans are considered "temperature guardians," and the electronic wires connecting them, though often overlooked, are the "hidden lifeline" determining their operational stability, safety, and lifespan. Whether it's computer mainframes, industrial control cabinets, home appliances, or automotive electronics, the selection of cooling fan wires is crucial. Especially in export-oriented markets, UL certification serves as a core safety endorsement for electronic wires, directly determining whether a product can enter the international market. Today, we focus on the application of UL electronic wires in cooling fan products, comprehensively unlocking key industry knowledge points from selection, product analysis, procurement pitfalls to high-quality supply.

Selecting cooling fan wires is not a matter of "making do." It requires comprehensive judgment based on power load, working environment, installation scenario, and certification requirements. Slight negligence can lead to overheating, short circuits, or even equipment fires. The core considerations mainly include the following four points:

The current needs to be calculated based on the fan power to match the appropriate wire diameter. A wire diameter that is too thin will increase resistance, causing energy loss to be converted into heat, reducing heat dissipation efficiency and accelerating wire aging; a wire diameter that is too thick will increase cost and is not conducive to installation in confined spaces.

Cooling fans operate in vastly different environments, including high temperatures, humidity, oil contamination, and acid/alkali corrosion, all requiring the wire to possess corresponding resistance. For example, fans in industrial workshops need to be temperature and oil resistant, while fans in outdoor equipment need to be moisture and mold resistant. This necessitates that the wire insulation material possesses corresponding properties; PVC and XLPE are common choices.

For cooling fans exported to markets like North America, their compatible wiring must be UL certified and meet standards such as UL758 and UL1581; otherwise, they will face market access barriers. This is a key reason why UL electronic wires have become the core choice for export-oriented fan manufacturers.

Among UL electronic wires suitable for cooling fans, UL1007 and UL2468 are the two most widely used models. With their precise parameter design and excellent overall performance, they have become the preferred solutions for different scenarios. Although both belong to the UL certification system, their structures and parameters have different focuses, and their applicable scenarios also differ.

Let's look at the UL1007 electronic wire first. As a representative of single-core round wire, its core parameters are practically "tailor-made" for small cooling fans. The conductor uses 32-16AWG single or stranded bare copper or tin-plated copper, offering excellent conductivity. The copper core cross-section is bright and has a soft color, and its resistance value is far lower than that of inferior products in the industry, effectively reducing power loss. The insulation layer is made of polyvinyl chloride (PVC), with a rated temperature range of 80℃-105℃ and a rated voltage of 300V-600V, easily handling the operating temperatures of conventional cooling fans. It has passed UL VW-1 and CSA FT1 vertical flame retardancy tests, demonstrating rapid self-extinguishing upon contact with an open flame, maximizing safety. Its significant features include uniform insulation thickness, easy peeling and cutting, and no need for complex tools during processing, greatly improving fan assembly efficiency. It also possesses acid and alkali resistance, oil resistance, moisture resistance, and mildew resistance, making it suitable for cooling fans in household appliances, computers, and small instruments. For small fans with limited space, our customers use UL1007 24AWG, 26AWG, and 28AW wires, perfectly meeting installation requirements without creating space redundancy.

As for the UL2468 electronic wire, as a parallel flat wire, its structural design emphasizes installation flexibility and multi-wire coordination. The conductors also utilize 32-16AWG single or stranded bare copper or tin-plated copper. The multi-copper wire stranded structure makes it far more flexible than UL1007, preventing conductor breakage or insulation cracking even after repeated bending. This makes it particularly suitable for cooling fans requiring frequent repositioning or bending installation, such as adjustable fans in industrial machinery and medical equipment. Its rated temperature is 80℃, rated voltage is 300V-500V, and the maximum conductor resistance at 20℃ is only 250Ω/km, demonstrating strong conductivity stability and suitability for signal transmission and power supply in medium-power cooling fans. The flat structure of UL2468 facilitates the parallel laying of multiple wires, making it especially suitable for intelligent cooling fans with speed control and temperature measurement functions. It reduces wire tangling, improves the neatness of internal fan wiring, and lowers the risk of insulation damage due to wire friction.

UL2468 In summary, UL1007 is more suitable for small, fixed-installation, low-to-medium power cooling fans, such as computer CPU fans and household appliance cooling fans; UL2468 is more suitable for medium power cooling fans that require flexible installation or intelligent control, such as industrial control cabinet fans and medical equipment cooling fans. Both cover the vast majority of cooling fan application scenarios.

Four Tips to Secure High-Quality UL Wires The market for UL electronic wires is rife with counterfeit and substandard products. "Non-standard products" lure companies with low prices but conceal safety hazards. Mastering the following four tips can help you accurately avoid procurement pitfalls and secure high-quality products:

High-quality UL wires must possess complete UL certification qualifications. Not only should you check the printed information on the wire, but you should also verify that the certification number can be checked on the UL website to ensure the product complies with standards such as UL758 and UL1581. The printed information should clearly indicate the company's UL file number, AWM, UL model, specifications, rated voltage, temperature, and manufacturer information to avoid counterfeit products.

High-quality UL wires have a neat and smooth appearance, with uniform insulation color and thickness, free from bubbles, scratches, or off-core defects. The conductor is bright reddish, soft, and resilient, showing no creases or breaks after repeated bending. A section of the insulation can be cut to check for air pockets; it should not tear easily when stretched. Inferior wires often use recycled materials for insulation, which is brittle and easily torn.

When possible, quality can be verified through simple tests: use a multimeter to measure the conductor resistance. The resistance value should meet the corresponding standard (e.g., UL1007 24AWG conductor resistance should meet industry standards). Excessive resistance indicates poor conductivity. A simple burning test can also be performed; high-quality UL wires will extinguish quickly after being removed from an open flame, while inferior wires will continue to burn.

Prioritize manufacturers with in-depth understanding of UL standards and extensive production experience. These manufacturers can provide selection advice based on the specific application scenario of the fan, and their product stability is more guaranteed. Also, pay attention to the manufacturer's production capacity, customization capabilities, and after-sales service to avoid supply delays or lack of after-sales support.

In the field of UL electronic wires, Guangdong Zhengfeng Wire & Cable Co., Ltd., with its profound technical expertise, stringent quality control, and comprehensive service system, has become the preferred partner for many cooling fan manufacturers, providing comprehensive solutions for their selection, procurement, and customization needs.

Regarding UL standard interpretation, the company has a professional technical team with years of experience in UL standards. They can accurately interpret the requirements of standards such as UL758 and UL1581, and, combined with the cooling fan's power, operating environment, and export destination, provide customers with targeted selection solutions, ensuring full compliance and helping them successfully penetrate the international market.

In terms of product assurance, the company adheres to a high-quality standard. All UL electronic wires use high-quality bare copper or tinned copper conductors, combined with premium PVC insulation materials, and undergo rigorous testing for temperature resistance, flame retardancy, oil resistance, and insulation to ensure stable operation in complex environments. Complete product certifications are provided, and each batch of products comes with a complete test report, giving customers peace of mind when purchasing.

In terms of product supply, the company offers a comprehensive range of UL electronic wires, including UL1007 and UL2468 standards, covering various wire diameters, materials, and lengths. Customization is also supported, allowing for the creation of wires tailored to specific customer needs based on their cooling fan structure and installation environment. Leveraging a mature production supply chain, the company ensures fast delivery, effectively guaranteeing customer production schedules and preventing capacity delays due to wire shortages.

Regarding service support, the company provides end-to-end pre-sales and after-sales services: pre-sales involve one-on-one communication with professional technicians to assist customers in product selection; during sales, real-time feedback on production progress ensures timely delivery; and after-sales technical support provides timely responses to any issues encountered during product use, comprehensively addressing customer concerns.

The stable operation of a cooling fans begins with a high-quality UL electronic wire. Choosing Guangdong Zhengfeng Wire & Cable Co., Ltd. means not only choosing superior products but also professional technical support and reliable cooperation.

Guangdong Zhengfeng Wire&Cable Co., Ltd.

Tel/WhatsApp/WeChat: +86 138 2929 2517 / +86 147 4930 7879

Email: manager01@wire-cablemanufacturer.com